SERVICE

Facilities

TAISEI KOGYO has production equipment, measurement equipment, and prototype / development equipment to meet our customers' requirements.

Production equipment

-

Sintering furnace

We have introduced batch type high vacuum furnaces capable of continuous degreasing and sintering process.

-

Bi-colour injection machine

The selection of materials is limited due to the effects of sintering behaviour and/or metal diffusion speed. However, by using a bi-colour injection moulding machine, it is possible to inject a component with different metal material or layered components.

| Facilities | Number of units |

|---|---|

| Kneading machine | 3 |

| Debinding furnace | 2 |

| Pelletizer | 3 |

| Sintering furnace | 6 |

| Firing furnace | 1 |

| Injection moulding machine | 9 |

| Extraction moulding machine | 1 |

| Barrel polishing machine | 2 |

Production equipment

-

Small injection moulding machine

For the study of new alloy powders and special powders, one pellet kneading / injection moulding machine has been introduced for samples weighing 10 g or less, and a compact moulding machine has been introduced for material up to 500 g.

We have experience in rare metals, nano-particle materials, new alloys, composites of metals and ceramics. -

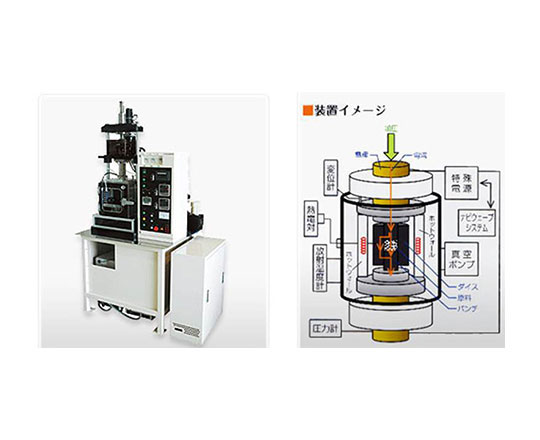

Spark plasma sintering (SPS) furnace

This is a sintering furnace for studying spark plasma sintering method. This SPS furnace can produce sintered parts in a short time.

-

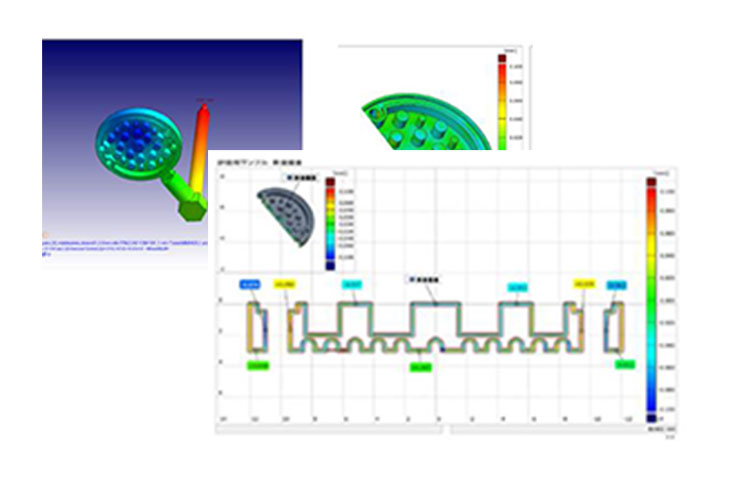

Flow analysis simulation

Since MIM fills a mould with a composite material of a metal powder and binder, which have greatly different specific gravities, analysis using general plastic flow simulation software cannot be directly applied to MIM simulations. TAISEI KOGYO, in cooperation with a MIM flow simulation software company, has realised high-accuracy, high-speed analysis of MIM components.

Evaluation equipment

-

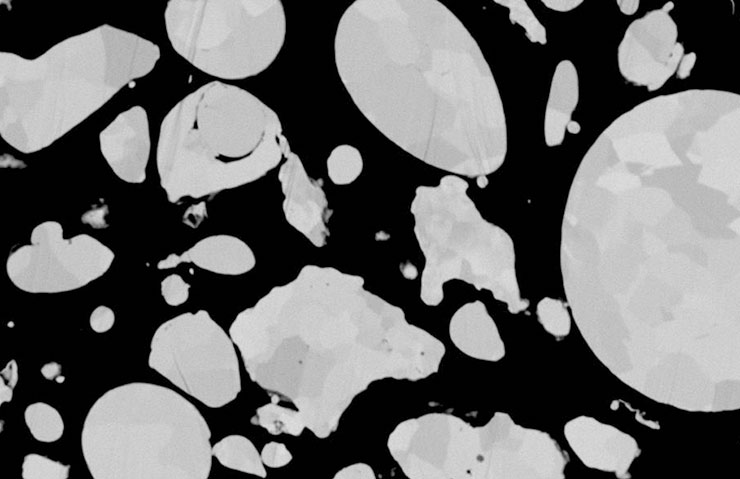

Scanning electron microscope

The sample surface is observed at high magnification by detecting secondary electrons and/or reflected electrons. An energy dispersive X-ray analyser is attached.

-

Energy dispersive X-ray spectroscopic device

It is an element analysis device detecting characteristic X-ray from element by being exposed to primary ray electricity or X-ray. It is equipped in the SEM system.

-

Ion milling

A flat measurement cross-section is processed with an argon ion beam.

-

Carbon analyser

The amount of carbon contained in the sample is measured in high accuracy.

-

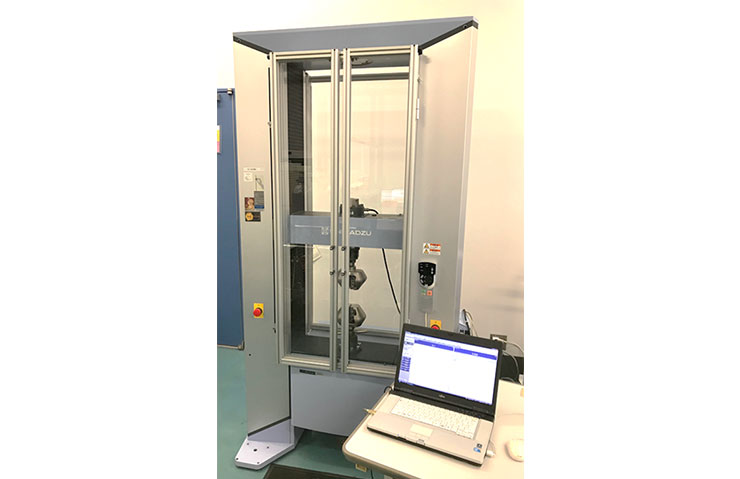

Universal testing machine

The most common equipment for tensile, bending and compression tests of metal material. We manufacture and measure new alloys specimens and evaluate Young's modulus, Poisson's ratio, yield strength, etc.

-

Viscosity measuring

The viscosity of the MIM feedstock is observed by MFR measurement, kneadability evaluation equipment, and fluidity evaluation equipment.

-

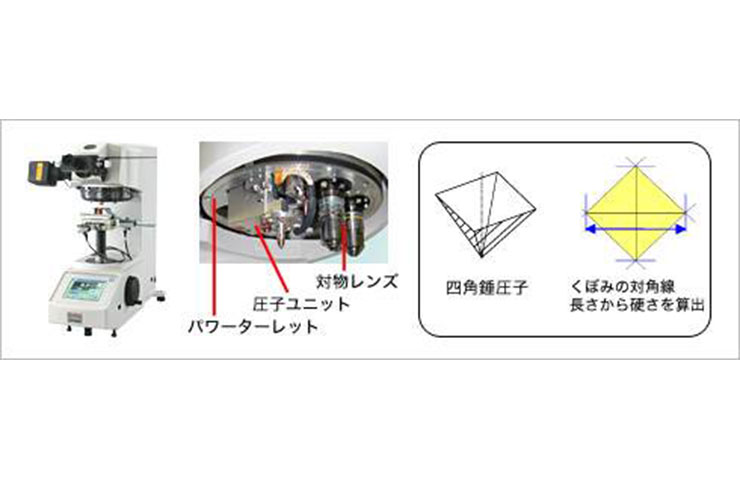

Hardness measuring

We have introduced a micro Vickers hardness tester to evaluate our fine metal parts.

-

Pycnometer

Automatic density measurement equipment is deployed.

-

Thermogravimetry

We employ a high-temperature suspended type thermogravimeter. It is also able to analyse in vacuum.

-

X-ray CT

A high measurement resolution X-ray CT system is deployed.

-

Optical 3D measurement

We deploy a 3D measurement system with the highest resolution in optical type.