SERVICE

What is MIM?

Metal powder injection moulding (MIM) is a manufacturing method for metal products by injection moulding material called feedstock, which is a mixture of metal powder and a binder made of resin, wax, etc., into a mould and sintering them.

MIM process

MIM Features

| Conventional MIM | Additional feature by μ-MIM® | |

|---|---|---|

| Material |

|

|

| Design |

|

|

| Injection moulding |

|

|

| Sintered body |

|

|

Accuracy and specifications

| Conventional MIM | μ-MIM® | ||

|---|---|---|---|

| Material | Length | <50mm |

<10mm Maximum 30mm in one direction |

| Thickness | 0.5~5mm | ||

| Minimum wall thickness | 0.3mm(partial) | 0.1 mm (6mm square) | |

| Smallest hole size | 0.3mm(partial) | Φ0.03mm | |

| Tolerance | < 5mm | +/- 0.03mm | +/- 0.01mm |

| 5-10mm | +/- 0.04mm | +/- 0.03mm | |

| 10-20mm | +/- 0.08mm | ||

| 20-30mm | +/- 0.15mm | ||

| Relative density(%) | 95-98 | > 98.5 | |

| Surface roughness (Ra) | < 3μm | 0.3μm(In case of applying ultra fine powder) | |

| Rmax | < 10μm | 2~10μm | |

| Product weight | < 50g | ≦ 10g | |

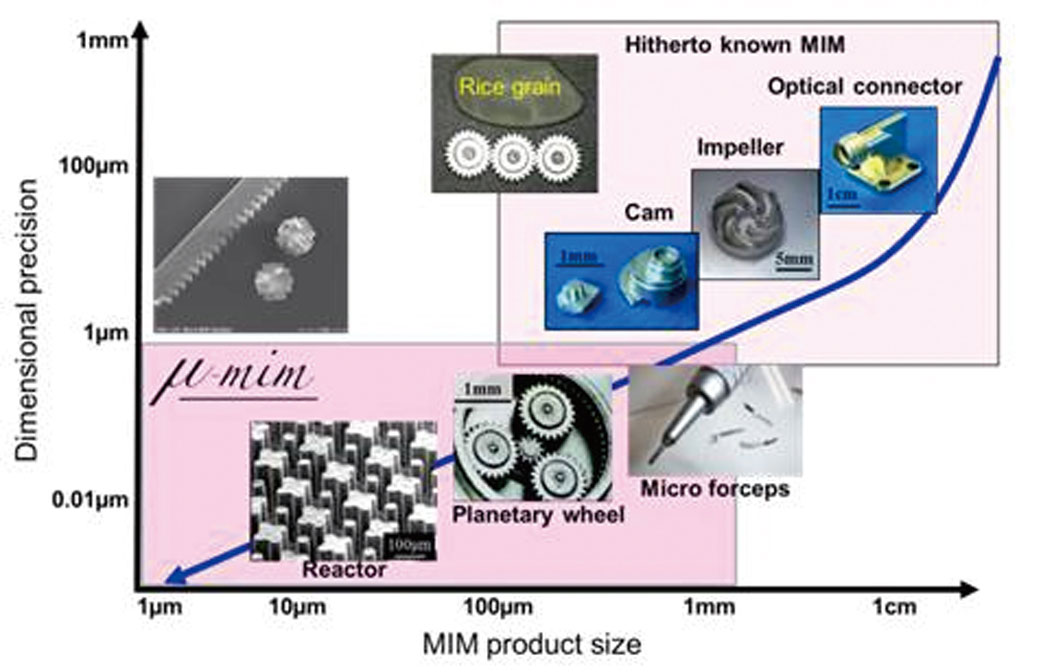

What is μ-MIM®?

μ-MIM® is a technology that realises ultra-precise MIM components. It is a technology that includes not only miniaturization of the product size but also its accuracy and quality assurance.

μ-MIM® meets the following demands.

- ▪ Mass production of components and materials that are difficult to machine

- ▪ Integration of small components that are difficult to assemble

- ▪ Mass production of components with size and tolerance requirements that are difficult by conventional MIM production

- ▪ Add value to components by integrating functions

In conventional MIM, most of the parts have a size of several millimetres to several centimetres and must satisfy the dimensional tolerance of

about 5-10% of its size.

The product size is smaller, the required tolerance is also smaller thus the difficulties of manufacturing is increased.

μ‐MIM® realises mass production in that area