SERVICE

3D-μMIM® application examples

3D-μMIM®(3D-metal injection moulding) is our original lost core method for producing parts with complicated undercuts and so on.

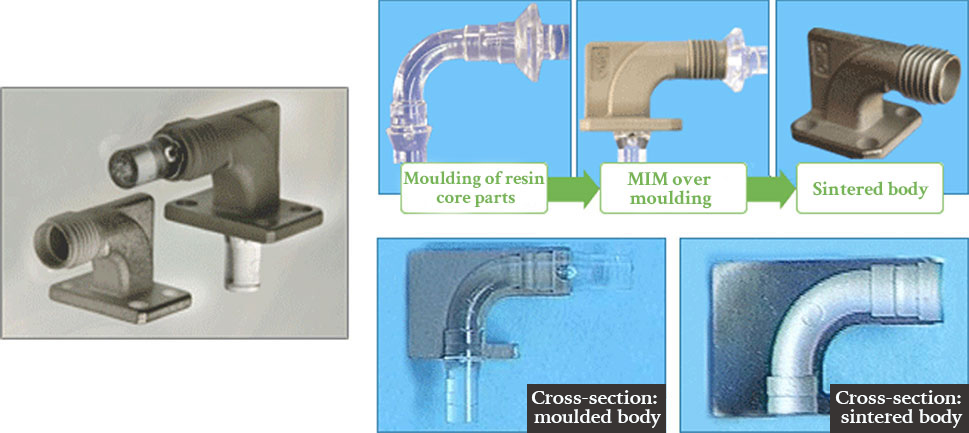

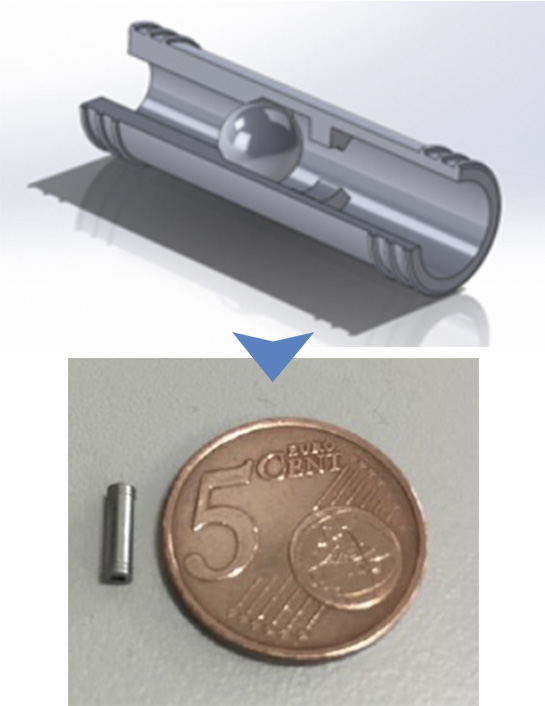

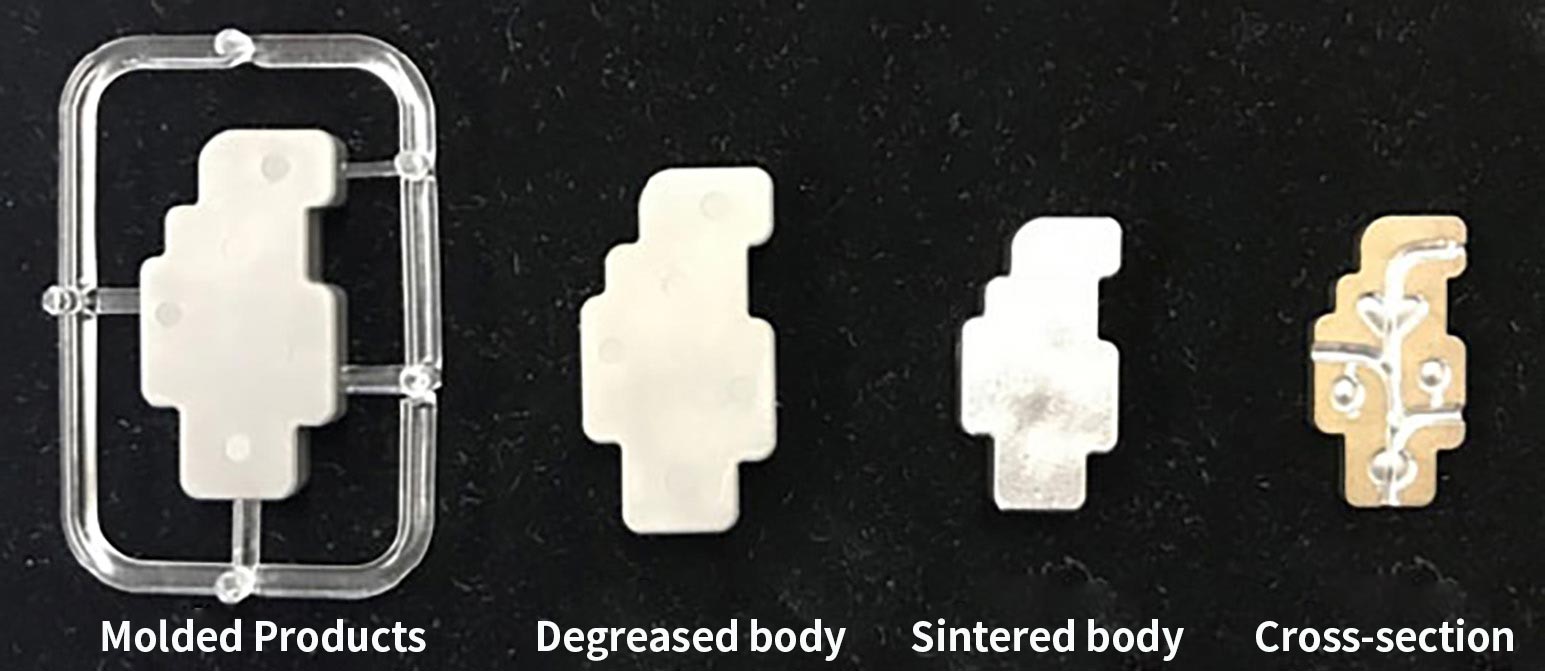

Check valve

Mass production of components with complex hollow design as follows

- 1. Special flow path including undercut

- 2. 0.2mm or less thin wall part

- 3. Different materials in the cavity

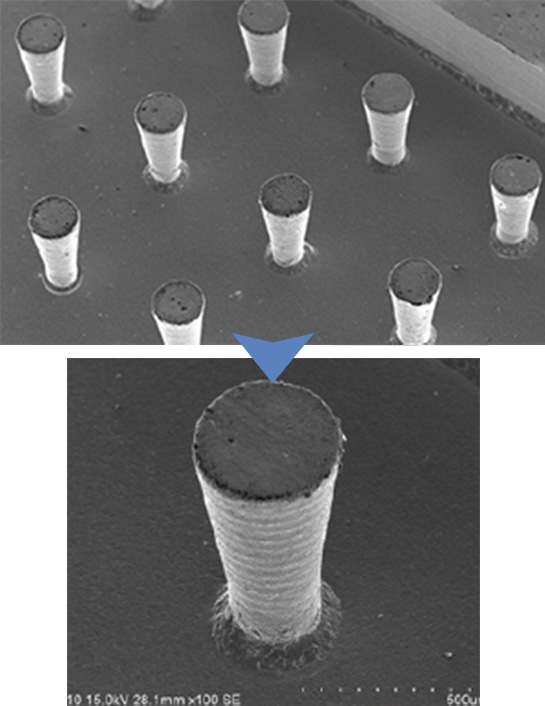

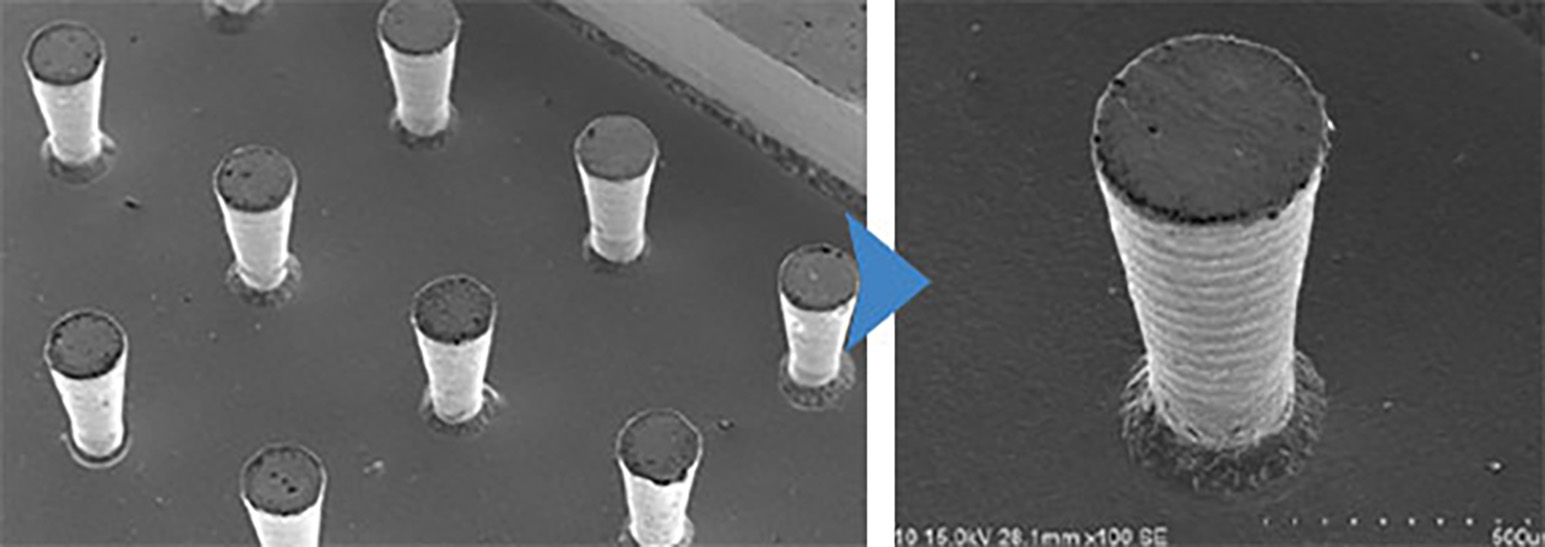

Reverse taper structure

A microstructure is placed on the surface to improve its functionality.

- 1. Increasement of surface area

- 2. Improvement of bonding strength with dissimilar materials by an anchor effect

- 3. Reduction of contact area

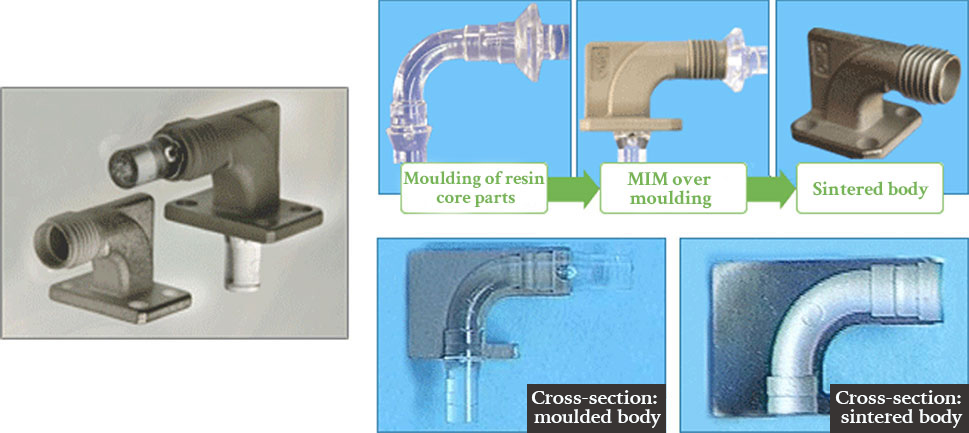

Nozzle/flow path

Mass production components with complicated internal channels.

- 1. Flow path with optimised fluid behaviour

- 2. Applicable for specially designed orifices

- 3. Difficult-to-cut materials like SUS, Ti are also available